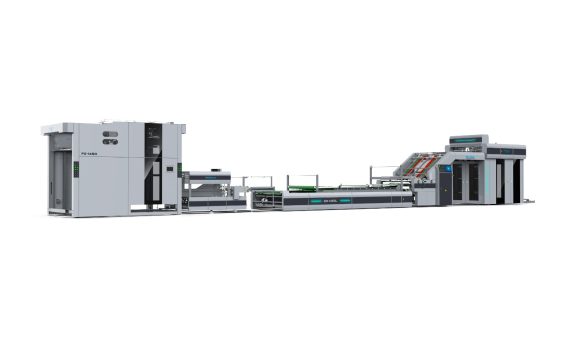

The machine is equipped with numerous servomotors that allow automatic adjustment of different parts of the machine for quick format changes and to reduce production start-up times.

Two servomotors make it possible to optically register the sheet with the card while the machine is running, without having to stop the sheet.

Thanks to its touchscreen, it offers very intuitive and precise operation.

It is equipped with a double pressing roller after the gluing section.

The top sheet transport is equipped with a suction system for more stable and precise transport.

The top sheet feed head is driven by a servomotor.

Parámetros técnicos de la máquina:

| Descripción | Especificación |

|---|---|

| Formato máximo de pliego (ancho x largo) | 1450mm * 1450mm |

| Formato mínimo de pliego (ancho x largo) | 360mm * 360mm |

| Gramaje de pliego inferior | 250g/m2 (aprox. 0,35mm*)-10mm (*Dependiendo del fabricante del material) |

| Gramaje de pliego superior | 120g-700g |

| Velocidad máxima* | 16000 pliegos/hora / 165m/min |

| Precisión de la máquina | ±1.0mm (para las hojas estándar) |

| Peso de la máquina | Aprox. 8000Kg |

| Dimensiones sin Flip-Flop (L × A × Al) | 15700mm * 2400mm * 2550mm |

| Voltaje | 380VAC/4P |

| Potencia | 26Kw |

| Cartón corrugado y soporte semirrígidos aplicables | A, B, C, E, F, 3 capas, 5 capas, otros tipos de soportes semirrígidos |

* Los datos técnicos pueden ser modificados por el fabricante sin previo aviso.

*La velocidad máxima depende del formato y tipo de producto.

Safety equipment

The machine is equipped with protective covers at various points to prevent possible injury to the operator.

Automatic paper feeding system

The input feeder is equipped with a pre-stacking system and a non-stop system to avoid production stoppages.

Servomotor for upper feeder stacking control

Uses a servomotor to automatically control the top stack of the feeder, making it rise with greater precision to ensure a stable distance between the paper and the paper sucker, guaranteeing a continuous and stable feed.

Double bearings and automatic lubrication system

Roller with an increased diameter of 150 mm and double bearings for greater stability.

The automatic lubrication system guarantees a longer machine life.

Corrugated cardboard feeder

The card feeder is driven by a servomotor for correct and precise feeding.

Digital settings

All settings are made and displayed on the screen. Such as glue volume, bottom/ top paper size, production log… In this way, the consistency of the different batches can be ensured, so that quality control becomes ever simpler and easier, and operator dependency is greatly reduced.

Electrical system

Complete servo control system developed in-house according to European standards. It has components from internationally recognised brands such as Schneider, Becker, Veichi, Fuji, Omron…

Option: flip flop with retraction system included.

For small production quantities, the machine allows the Flip-Flop to be switched off for manual retraction into the press blanket.

The transport part towards the Flip-Flop retracts, allowing it to be repositioned when necessary.

Are you looking for detailed information about this machine or any other from our catalog?

Please fill out the following form and our sales team will provide you with all the information you need. Whether you are interested in specific features, pricing, or stock availability, we are here to help you make the best decision for your business. Feel free to contact us!

Controller: The personal data you provide will be processed by IMAGRAF Maquinaria, S.L.

Purpose: Solely to respond to the questions you raise through the contact form.

Legitimacy: By checking the box 'I have read and accept the privacy policy,' you are giving your consent for your data to be processed according to the aforementioned purpose.

Recipients: As a user and interested party, we inform you that the data you provide us will be located on the servers of Clouding.io (Cloudi Nextgen, S.L.) in their Barcelona data center, within the EU. See the Clouding.io privacy policy.

Rights: We remind you that you have the right, among others, to access, rectify, limit, and delete your data whenever you wish.

Additional information: You can find more detailed information about Data Protection in our privacy policy.

IMAGRAF is dedicated to the sale and repair of graphic machinery.

CONTACT US

C/ Curros Enríquez, 9

15888 Oroso (A Coruña)