COMMERCIAL PRINTING MACHINERY

Welcome to Imagraf’s commercial printing machinery section! We are dedicated to providing high quality solutions to meet your graphic and labeling needs. We have a wide variety of high quality machines for printing, cutting, double-sided tape application, laminating, UV varnishing, folding, collating, magazine forming and binding processes.

COMMERCIAL PRINTING

At Imagraf we offer a wide variety of high quality machines to meet your needs in label printing and finishing processes. With a focus on innovation and performance, each of our machines is designed to give you optimal performance and maximum efficiency in your labeling projects. Discover our cutting-edge solutions and power your label production with the best technology on the market.

Tipos de máquinas

BINDING MACHINES

Imagraf’s binding machines for Commercial Printing are essential in the production of printed materials such as books, magazines, catalogs and brochures. These machines allow binding printed sheets efficiently and accurately, guaranteeing a professional and durable finish on each product. Imagraf offers a wide range of binding machines adapted to different types of finishes, such as paperback, Wire-O, wire stitching, three-side trimming and hard cover.

The use of binding machines in Commercial Printing guarantees the quality and finish of printed materials, allowing customers to offer high quality products and differentiate themselves in the market, improving their positioning and profitability.

Softcover

Imagraf’s softcover binding machines allow the printed sheets to be joined by means of adhesives, such as hot or cold glue, and a flexible paper or cardboard cover. This type of binding is common in paperbacks, magazines and catalogs, and offers an economical and high quality solution.

Wire-O

Imagraf Wire-O binding machines facilitate the binding of sheets by means of a spiral wire, which allows the pages to turn 360 degrees and remain flat. This type of binding is ideal for diaries, notebooks and instruction manuals.

Thread stitching machine

Imagraf thread stitching machines allow the sheets to be joined together by thread, creating a solid and durable binding. This method is common in high quality books, such as luxury editions or art books.

Hardcover

Imagraf hardcover binding machines allow you to create books with a rigid cover, offering an elegant and durable presentation. This type of binding is common in textbooks, special edition novels and photo albums.

COLLATOR

Imagraf’s Commercial Printing Collators are essential machines in the production process of printed materials such as brochures, magazines, catalogs and books. These machines have the function of arranging and stacking printed sheets efficiently and accurately, facilitating their further processing, such as binding, assembly or packaging. The correct organization and stacking of sheets is essential to ensure the quality and presentation of printed products.

Imagraf’s collators have control and adjustment systems that allow them to adapt to different sheet sizes and formats, as well as to different types of materials and weights. These machines are designed to work with great speed and precision, reducing production times and improving efficiency in commercial printing. In addition, Imagraf’s collators incorporate error detection and correction systems, such as double or missing sheets, guaranteeing the quality and integrity of the printed products.

The use of collators in commercial printing is a profitable investment, since they optimize the workflow and ensure the correct organization and preparation of printed materials for further processing. The efficiency and precision of Imagraf’s collators allow customers to offer high quality products and differentiate themselves in the market, improving their positioning and profitability.

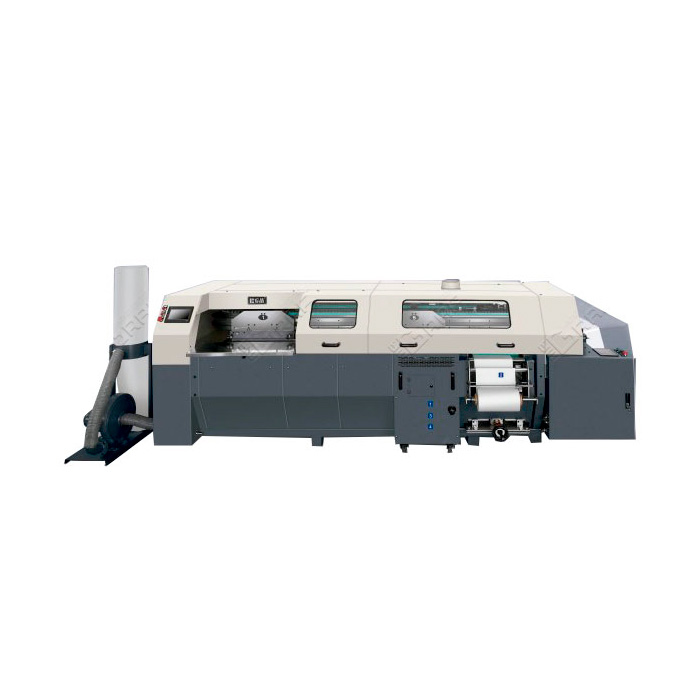

CUTTING

Imagraf’s cutting machines for Commercial Printing play a fundamental role in the production of high quality printed materials, such as brochures, magazines, catalogs and books. These machines guarantee a precise and clean cut on a wide variety of materials, from paper and cardboard to corrugated paper and other substrates. Imagraf offers different types of cutting machines, such as trimmers and laser cutters, to suit the specific needs of each project and customer.

Imagraf trimmers are cutting machines that allow processing large quantities of paper quickly and accurately. These machines are designed to withstand intensive use in commercial printers and feature high-precision safety and measurement systems to ensure optimal results in each cut. On the other hand, Imagraf laser cutters offer high-precision cutting, especially on delicate or intricate materials, such as heavyweight cardboard, featherboard or synthetic materials. Laser cutters are ideal for jobs that require a high level of detail and precision, such as cutting complex shapes or high quality finishes on packaging and stationery products.

DOUBLE-SIDED TAPE APPLICATOR

Imagraf double-sided tape applicator machines are an essential tool for the printing industry, as they facilitate the application and mounting of printed materials in a wide variety of applications. These machines allow double-sided adhesive tape to be applied accurately and uniformly to different types of materials, such as paper, cardboard and plastic, improving production efficiency and ensuring a professional finish.

The technology of Imagraf’s double-sided tape application machines adapts to the specific needs of each project, offering solutions for jobs of different sizes and formats. These machines are equipped with control and adjustment systems that guarantee the correct application of the adhesive tape on each material, reducing waste and improving productivity. Double-sided tape applicators are especially useful in the production of materials such as advertising displays, image montages, signage and other products that require a firm and durable bond between different layers or elements.

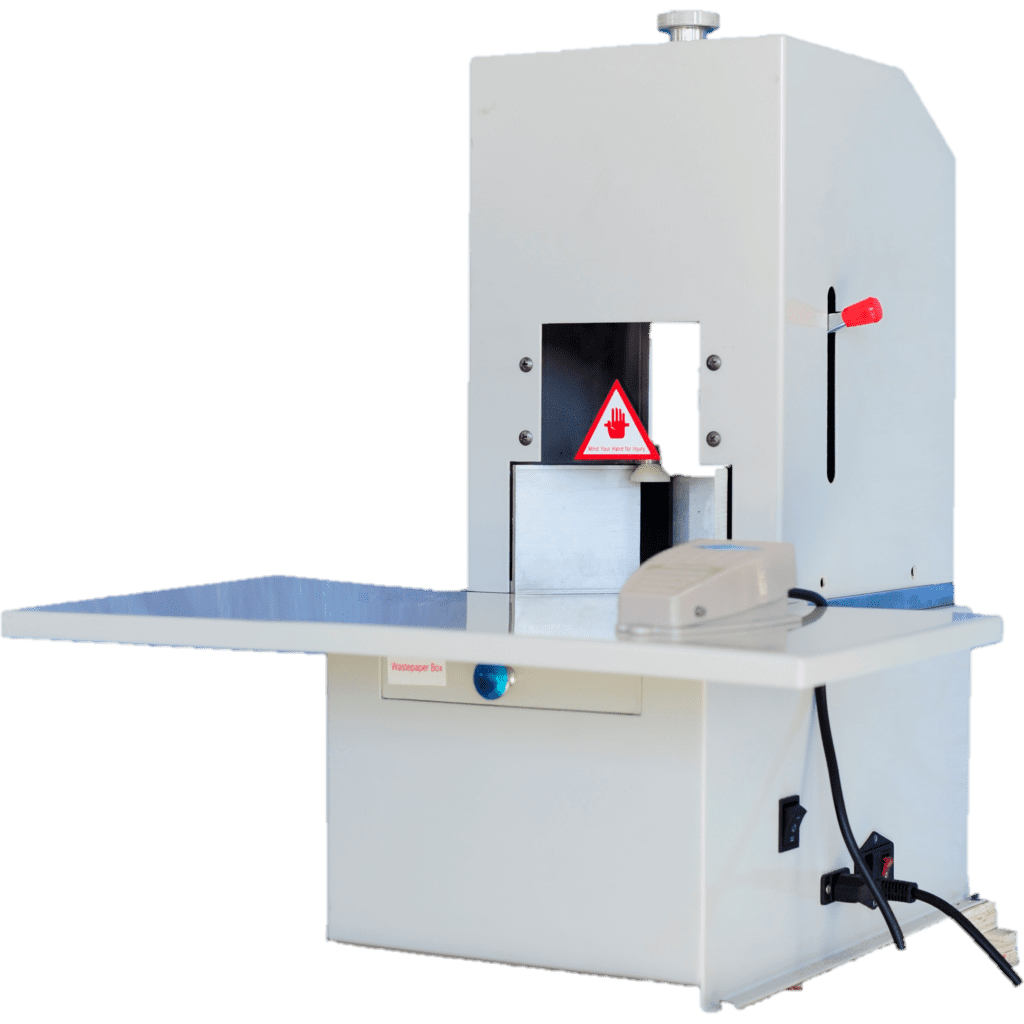

FOLDING

Imagraf’s folding machines for Commercial Printing are indispensable in the production of printed materials such as brochures, magazines, catalogs and books. These machines allow folding and creasing printed materials accurately, quickly and uniformly, facilitating their handling, presentation and transportation. The folding process is essential for shaping printed products and improving their functionality and aesthetics.

Imagraf’s folding machines are equipped with control and adjustment systems that allow configuring the type of folding and the number of folds according to the needs of each project. These machines are capable of performing a wide variety of folds, such as accordion, window, cross or map folds, adapting to different formats and applications. In addition, Imagraf folding machines are designed to work with different types of materials and weights, from thin paper to thicker cardboard.

The use of folders in Commercial Printing speeds up the production process and guarantees a professional and uniform finish on all printed materials. The versatility and efficiency of Imagraf’s folding machines allow customers to offer high quality products and differentiate themselves in the market, improving their positioning and profitability.

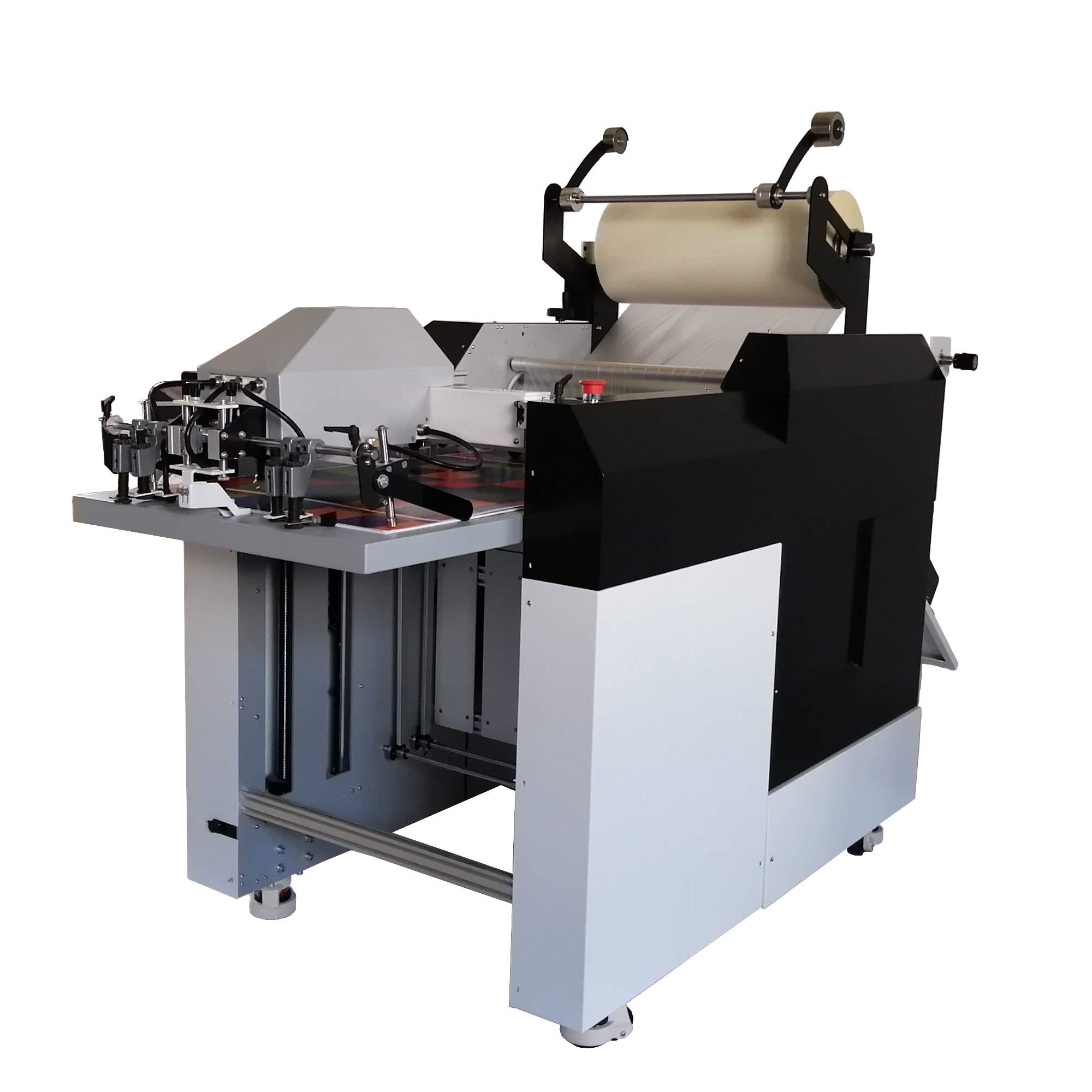

LAMINATING

Imagraf’s laminating machines for Commercial Printing are essential to improve the appearance and durability of printed materials. These machines apply a thin protective layer of plastic or polymer on the surface of printed materials, such as brochures, magazines, catalogs and books, protecting them from external factors such as wear, humidity and contact with chemical substances.

Laminating is a process that adds value to printed products, as it not only protects them, but also enhances their appearance and quality. Imagraf’s laminating machines offer different finishing options, such as gloss, matte or textured, to adapt to the needs of each customer and project. These machines have control and adjustment systems that guarantee the correct application of the laminate on each material, offering professional and uniform results at all times. The use of laminating machines in Commercial Printing allows customers to differentiate their products and increase their attractiveness in the market, improving their positioning and profitability.

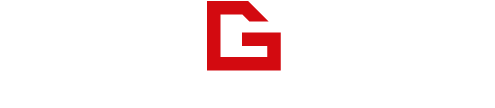

MAGAZINE BOOKLET MAKERS

Imagraf’s booklet makers for Commercial Printing are key machines in the production of magazines, newspapers and other periodicals. These machines facilitate the process of assembling, folding, stapling and cutting pages, guaranteeing a professional and high quality finish for each publication. The efficiency and precision of booklet makers are fundamental to ensure customer satisfaction and profitability in the publishing market.

Imagraf’s booklet makers are equipped with control and adjustment systems that allow them to adapt to different paper sizes, formats and weights, as well as to different types of binding and finishing. These machines are designed to work with great speed and precision, reducing production times and improving efficiency in commercial printing. In addition, Imagraf’s booklet makers incorporate error detection and correction systems, such as double or missing sheets, ensuring the quality and integrity of the publications.

The use of booklet makers in commercial printing is a profitable investment, since they optimize the workflow and ensure the correct production and finishing of periodicals. The efficiency and precision of Imagraf’s booklet makers allow customers to offer high quality products and differentiate themselves in the market, improving their positioning and profitability.

UV COATING

Imagraf’s UV varnishing machines for Commercial Printing are an efficient and versatile solution to improve the appearance and protection of printed materials. UV varnishing is a process that consists of applying a layer of ultraviolet varnish on the surface of printed materials, such as brochures, magazines, catalogs and books, and then curing it by means of ultraviolet light. This process provides additional protection against wear, scratches and stains, as well as enhancing the appearance of the final product.

Imagraf’s UV varnishing machines offer a high degree of precision and uniformity in varnish application, ensuring high quality results every time. These machines are capable of applying different types of UV varnish, such as gloss, matte or special effects, allowing customers to customize the finish of their products according to their preferences and needs. In addition, the UV varnishing process is fast and efficient, which reduces production times and improves profitability in Commercial Printing. The use of UV coating machines allows customers to differentiate their products and stand out in the market, offering printed materials with an attractive and durable finish.